DIY Mechanic - Changing Struts

Published: Sunday, October 05, 2025When braking on a highway offramp, my brake pedal and steering wheel shook, so I took it to Hyundai for an inspection. They told me I needed new front brakes (rotors and pads, $800 plus tax), and new front struts ($1750 plus tax). My stomach ached. I got quotes from other garages and they were all within $1,300 - $2,500. I wasn’t paying that when it was still capable of driving without issues.

I found a lot of youtube videos demonstrating how to change front struts on my car’s year/make/model. It seemed easy, I didn’t even need to climb underneath my car, or disassemble any auto body parts. I needed some tools.

Canadian Tire, Home Depot, Facebook Marketplace, Kijiji - all these places were selling tools for their weight in silver. I got lucky and found a tool-rental shop near me which also happened to sell tools too. I bought a racket-socket set for $20, and a few individual sockets I needed but weren’t in the set for $2 ea. I got the new struts for $125 ea from rockauto.com. I also got new sway bar links for $30 ea too. Shipping was kinda expensive at $100.

I live in an apartment with not enough space to do this kind of work in the parking lot, so I drove my car to a nearby community center with a flat parking lot and got to work at 5pm.

I was a noob at this point. I didn’t know sockets came in 3/8in and 1/2in sizes, or that cheap tools break, or how to do this operation with only 1 jack stand.

Here are some tips for other noobs,

- If you’re using cheap tools, or don’t know if you are using good tools, have multiples (sockets, ratchets, etc.)

- Two jack stands for this job is required. One to lift the car, another to lift the car’s “lower arm” to release compression on the strut-knuckle bolts, and insert sway-bar-links.

- When raising your car, stacked wood can be a good safety. Should the

jack(s) fail, the car should rest on the wood, and save you and your

brake rotors.

- I didn’t have enough wood, so I used a steel car wheel I found, and rested a wooden 2x8 on it.

- Bi-hex sockets are shit because they strip easily. Avoid them.

- Start early in the day when you have lots of light.

- Remember to hydrate.

- Padded work gloves are needed. In videos, mechanics just use vinyl kitchen gloves. Those won’t protect you enough.

- An impact drill is not needed, but would be really nice.

- You need to be physically fit to get the whole job done in a day if

you aren’t using power tools.

- I was just using a jack, torque wrench, and ratchets. I was exhausted after this, and I have worked out several times a week for many years.

- Buy sway bar links with a wrench snap-on. Cheap ones will keep

turning as you tighten them, despite an allen key being used to prevent

that.

- Only one of my sway bar links could be tightened to 80ft-lbs. I am still waiting on OEM links to arrive in the mail to change them out.

- WD-40 likely helps loosen up all the rusty bolts. I’d say this is needed too. Get it at the dollar store.

I drove my car 20km and everything seems ok. I might not need a wheel alignment after this.

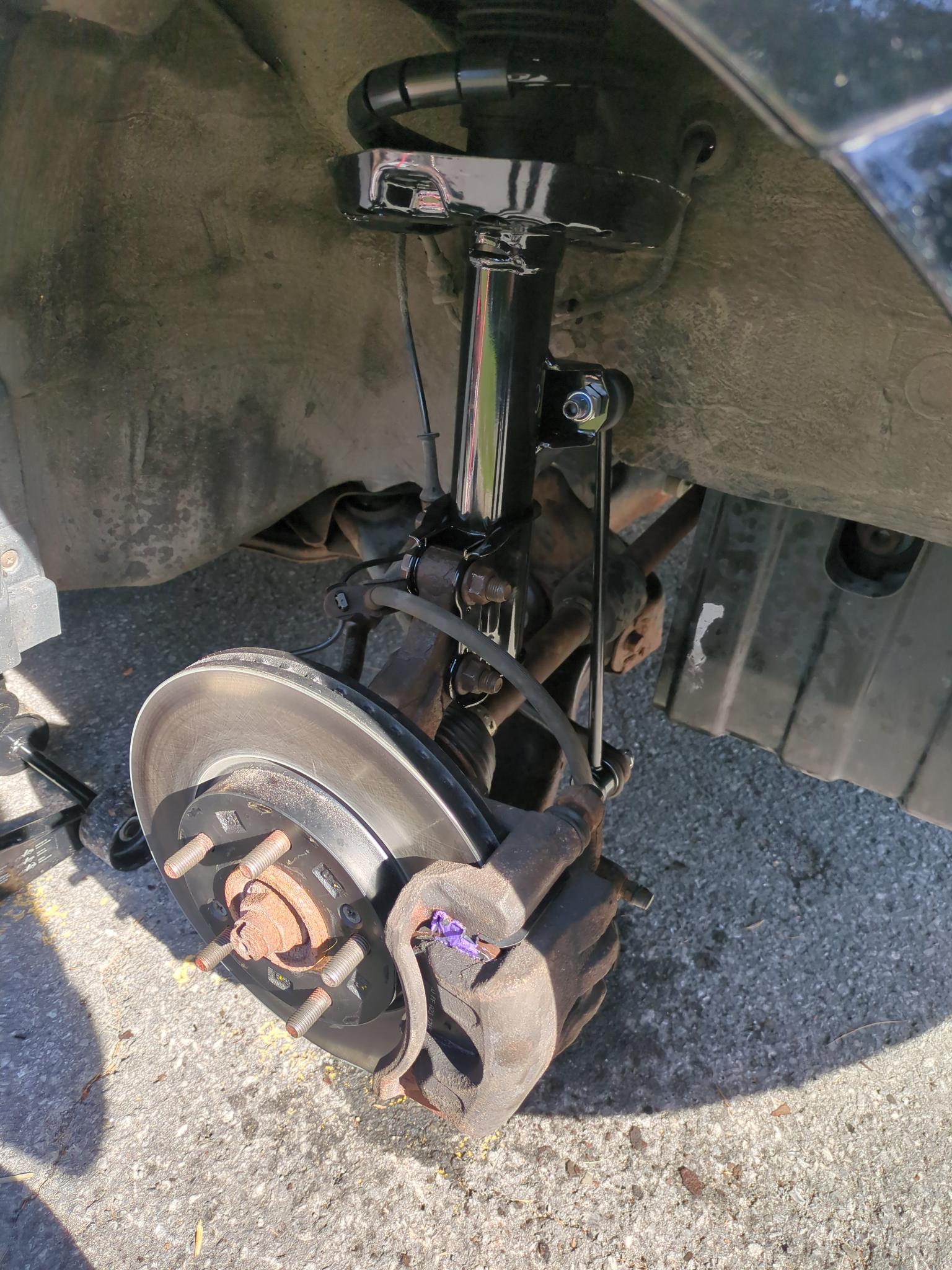

Here are some photos.

Old and rusty.

The snapped spring.

My workspace.

The final result.